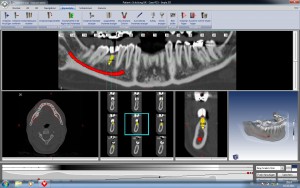

The manual or stereolithographic production of drilling templates for navigated implant placement is now state of the art. Now the increasing distribution and user-friendliness of CAD programs in connection with exportable data from implant planning programs also allows the production of CAM-milled templates. The new manufacturing process was verified as part of a fully digital workflow within a Masterthesis [1] under clinical conditions. The measured values for accuracy in comparison with the conventional methods [2] are to be assessed as a positive development.

The preconditions for a milled drilling template are:

• DVT/CT-Scan of the Jaw

• Implant planning program with STL output function of the

planned case (Impla 3D,

Schütz Dental GmbH)

• Impression and / or scan

of the jaw

• Software for comparison

• Moderation software

• Five axis milling machine (3+2 Axis)

In the case of a natural residual toothpost or special interim implants (Impla, Schützdental) because of a toothless jaw, the patient can be X-rayed without a scanning template. This leads to the advantage of being able to create a template even after the CT or DVT data are found.

New material:

medical light metal

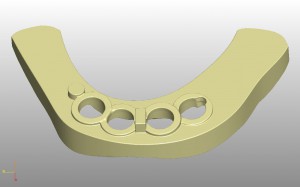

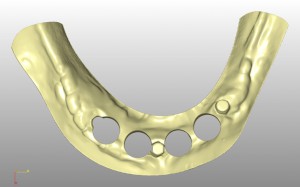

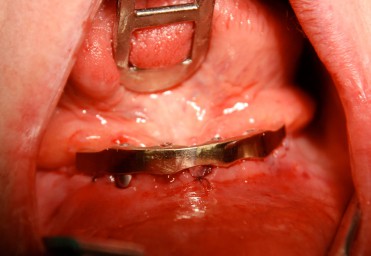

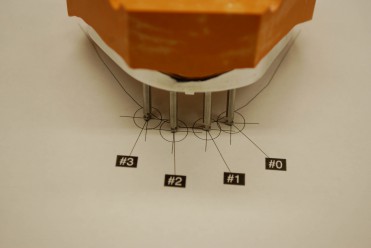

After reading the dicom data and the case planning by the surgeon, the digital or conventional impression is taken. The data are matched, the template is modeled virtually, and finally milled on a five-axis milling machine from the material in question, for example PMMA, medical light metal or titanium.

Digital processing makes it possible to implement all implant systems guided and full guided. There is no additional cost for sleeves if a full-guided implant system with medical aluminum is used. A template made of this material can be greatly reduced in diameter.

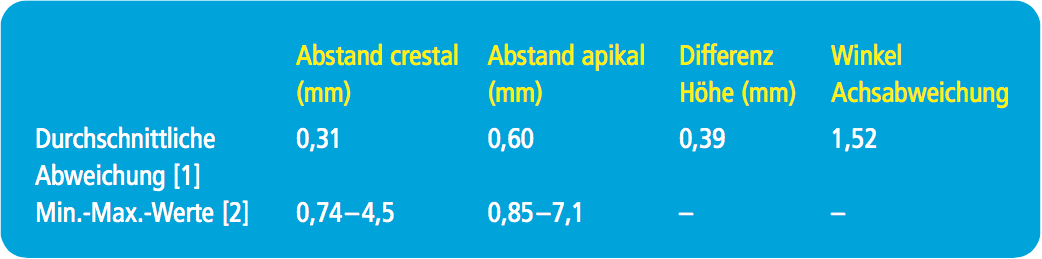

It is absolutely unbreakable, storage and shape-resistant, and can also be fractionated autoclavably according to RKI recommendations. Due to the high precision (Table 1), especially after measurement of the temporomandibular joints (Zebris, Schütz Dental), an immediate provisional care is also to be evaluated more clinically.

The first public presentation of the new manufacturing process took place at the Rapid Tech 2011 in Erfurt. The scientific evaluation of the precision over five patient cases with a total of 25 implants compared to results of previous publications was made in the master thesis of Prof. Dr. Dr. S. Haßfeld, Dortmund, and Dr. R. Grimm, Bochum. This work enables, among other things, the comparison of static and optical navigation systems with regard to accuracy.

The documented clinical cases in which the digital workflow was used to make a CAD/CAM milled template provide an optimistic outlook on the future of a fully digitalized rehabilitation of a patient with implant-supported dentures.

LITERATURE

(1) Grimm R, Hoßfeld S. The completely digitized creation of surgical drilling templates for three-dimensionally navigated implantation. (Publication of this work in preparation, Expected in the first quarter of 2012)

(2) Jung RE, Schneider D, Ganeles J, Wismeijer D, Zwahlen M, Hammerle CHF, Tahmaseb A, Computer Technology Aplications in Surgical Implant Dentistry. Abstract, Issue 7. Int J Oral Maxillofac Implants Suppl 2009;24.

ZT Hans Raapke

John Cooper Dental

Altenberge

E_MAIL: info@cooperdental.de